Inhalt

Julia Eberle

Marketing Manager

Your partner for ERP and technology..

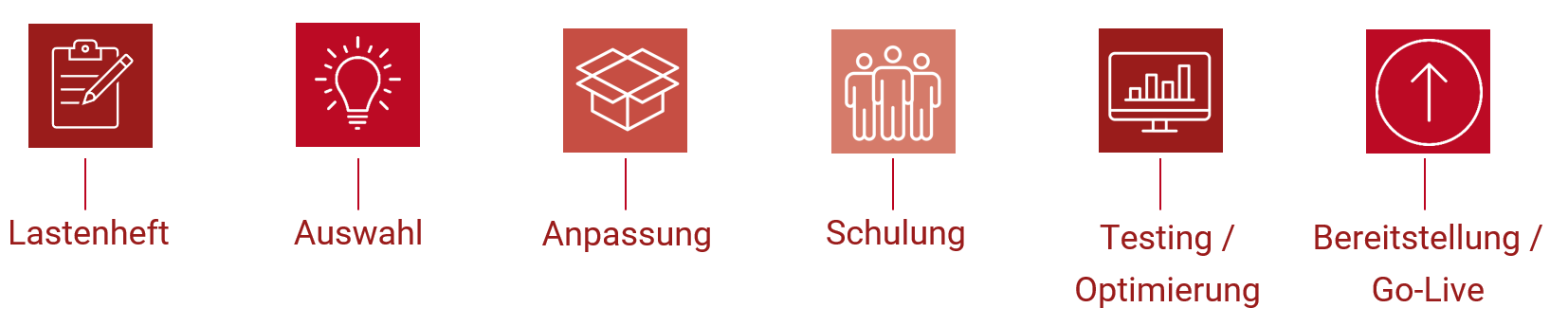

We look at the process from the specifications to go-live as well as the opportunities and risks

The introduction of an ERP (Enterprise Resource Planning) system is a major challenge for any company. It is not only about the technical implementation, but also about the organizational change and the training of the employees. In this blog post, I will take a closer look at the process of an ERP system implementation from the specifications to the go-live as well as the associated opportunities and risks.

For whom is ERP system suitable

An ERP (Enterprise Resource Planning) system is primarily suitable for companies of any size that want to make their business processes more efficient and transparent. Especially for companies with complex business processes, such as production or trading companies, an ERP system can provide enormous support.

An ERP system can help integrate and centrally control various business processes such as finance, purchasing, sales, production and warehousing. This allows companies, for example, to better manage their inventory, optimize supply chains, automate production processes and use their resources more efficiently.

An ERP system can also be a wise investment for companies looking to grow and expand. By integrating and standardizing business processes, companies can better respond to changes and react faster to new market conditions.

Another aspect in favor of an ERP system is the increasing digitalization of business processes. An ERP system can help integrate and centrally manage the data and information from various systems and applications. This enables companies to improve their data quality, for example, and to carry out their business processes more quickly and easily.

Let’s now take a closer look at the steps of ERP implementation:

Step 1: Analysis

Before a company decides on a particular ERP system, the requirements must first be defined. For this purpose, a specification document is created that describes the functionalities and processes that the system should cover. This document forms the basis for the subsequent selection of the appropriate ERP system.

Step 2: ERP system selection

After the specifications have been created, the search for a suitable ERP system can begin. In the process, different providers and their systems should be compared with each other. Important criteria for the selection are functionality, scalability, integration with other systems and user-friendliness. The price also plays an important role in the decision.

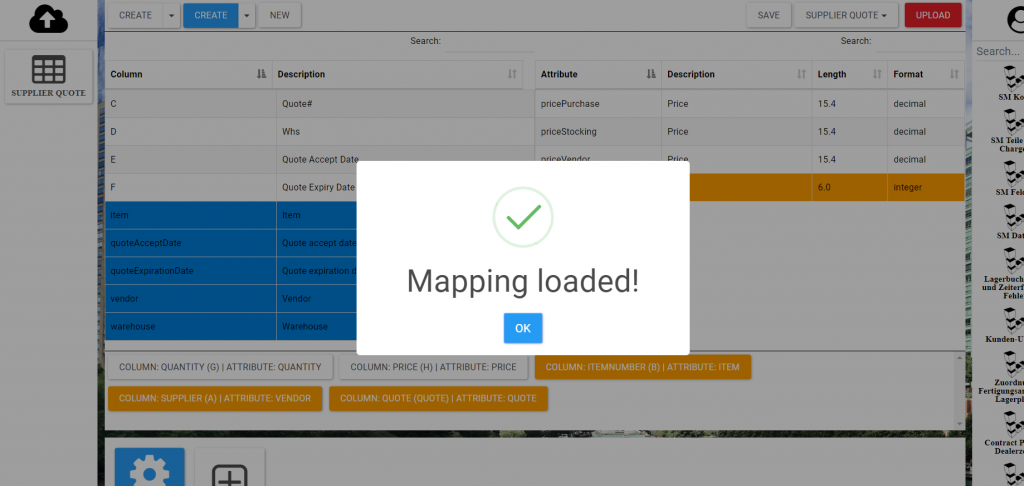

Step 3: Customization of the ERP system

Once the right ERP system has been selected, it must be adapted to the company’s specific requirements. This involves configuring the system, adapting the business processes and integrating it with other systems. It is important here that all departments of the company are involved to ensure that the system can be used efficiently for all parties involved.

Stept 4: Employee training

To ensure that all employees can use the new system effectively, comprehensive training is necessary. This should include not only the technical aspects, but also the processes and workflows in the company. Good training can help ensure that the ERP system is implemented quickly and successfully.

Step 5: Testing and optimization

Before the ERP system is put into operation, it must be tested extensively. This involves not only the technical functionality, but also the adaptation to the specific requirements of the company. During testing, weaknesses and optimization potential can be identified, which should be remedied before go-live.

Step 6: Go-Live

After the ERP system has been successfully tested, it can be put into operation. It is important that all employees are informed about the changeover and that there are no business interruptions during the changeover. Good preparation and planning can help to ensure that the go-live runs smoothly.

Chances of a ERP system implementation

An ERP system implementation can offer many opportunities for a company. By integrating business processes into one system, information can be shared more quickly and efficiently. The system enables better planning and control of resources, which can lead to greater efficiency and productivity. Process transparency can also be increased as all information is centralized and available in real time. In addition, an ERP system can provide a better basis for decision-making, as all relevant data is brought together in one system.

Another opportunity of an ERP system implementation is the standardization of processes. By adapting processes to the system, inefficient or redundant steps can be eliminated. This can lead to reduced process costs and increased consistency of results.

Another benefit of an ERP system is the ability to integrate with other systems. For example, data from the sales system can be integrated with the ERP system to provide a better overview of the entire business process.

Risks of a ERP system implementation

However, the introduction of an ERP system can also involve some risks as well as challenges. A common problem is underestimating the effort and costs involved in implementing an ERP system. Dependence on a single system and vendor can also be a risk, especially if there are glitches or outages.

Another risk is the lack of employee acceptance and commitment. Switching to a new system usually requires a change in workflows and processes, which can be perceived as stressful by many employees. Comprehensive training and communication can help overcome these challenges.

Another risk of an ERP system implementation is the lack of fit between the system and the company’s specific requirements. Especially with complex business processes, it can be difficult to optimally adapt the ERP system. Careful analysis and adaptation of the processes can help to minimize this risk.

Summary ERP system implementation

The introduction of an ERP system is a complex task that must be well planned and implemented. Careful analysis of the requirements, selection of the appropriate system, adaptation and training of the employees, and implementation of tests and optimizations are crucial for the success of the ERP system implementation. However, there are also risks, such as underestimating effort and costs, lack of employee acceptance, and the system not fitting the company’s specific requirements. These risks can be minimized through comprehensive planning and communication. Overall, however, the introduction of an ERP system offers many opportunities for a more efficient and transparent organization of business processes.

Infor Certified Channel Partner

We already have many years of experience with the flexible Infor ERP solutions.. The solutions Infor LN and Infor XA help with a successful development of your production and the modernization of your company. We also have exactly the right solution for your requirements.

SAP Silver Partner

The „youngest child“ in our ERP portfolio is the SAP ERP solution SAP Business ByDesign. We have been an official SAP Silver Partner for some time now. The SAP cloud ERP platform for your smart business processes. SAP Business ByDesign is a cloud-based ERP system designed primarily for small & medium-sized businesses.

We are your contact for ERP

Walk together with us in the direction of digitization!

We are your technical advisor and competent contact in matters of ERP and digitization.

Oder get in touch with us directly!

Marcel Kosel

Sales Manager